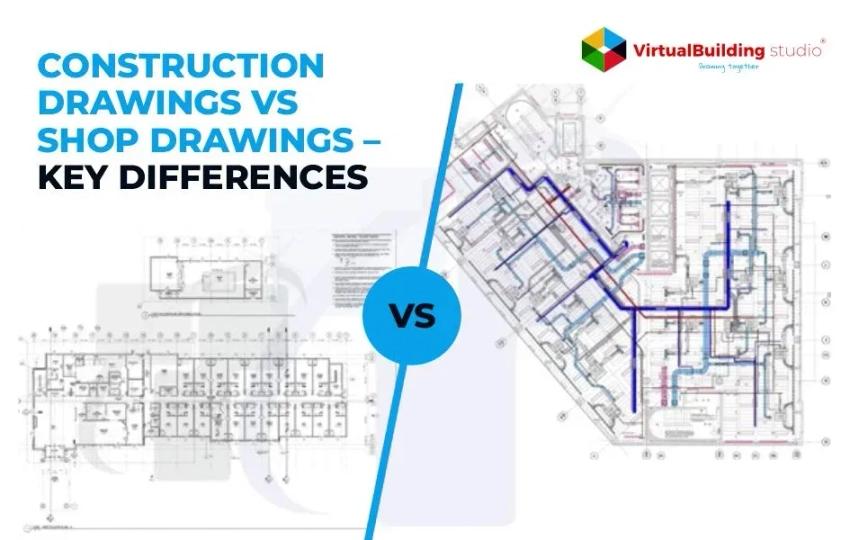

Before the construction work is initiated on-site, a plethora of drawing sets are generated, each with its significance and use. Different stakeholders use these drawing sets for successful building completion. For someone who is a part of the AEC industry, terms like shop drawings and construction drawings are quite common.

Architects prepare construction drawings to explain the overall design intent, and shop drawings are prepared by contractors to represent field executables. CAD drawing services are crucial for constructing large-scale and complex structures.

What are Construction Drawings?

- Construction drawings, also referred to as working drawings, visualize the architectural elements in a two-dimensional plane, before the actual construction begins.

- Some of these are also called IFC drawings or drawings issued for construction.

- These drawings depict the architectural components with precision and accuracy for detail-oriented decision-making.

- The drawings illustrate the structural use, appearance, features, fixtures, materials, estimated dimensions, equipment performance, and connections to other building components.

- These drawings outline the results of the ongoing work on the construction site and the final deliverables.

- The construction drawings also serve as bid drawings for contractors to estimate the project expense, including material consumption, labour cost, and construction costs.

What are Shop Drawings?

- Shop drawings, also known as fabrication drawings, are a set developed to interpret the actual design intent, field conditions, and project-related information.

- These drawings ensure that all components are planned as per the accepted industry standards and laws.

- The information generated with these drawings helps the fabricators in achieving accurate coordination, assembly, fabrication, and installation.

- This set of drawings is an extended version of the construction drawings with detailed information about beams, trusses, joinery, and equipment details.

- Every subcontractor submits their own set of shop drawings for review and approval.

- These drawings are significant for fabricators to understand the component manufacturing and installation during construction.

- The drafting process for shop drawings demands a higher level of accuracy, as they include more detailing than IFC drawings.

Advantages of Construction Drawings

Cost Efficient

The construction drawings are cost-efficient in comparison to the shop drawings, making them suitable for the initial conceptual and design stages.

Entire Project Overview

The construction drawings include architectural, structural, and MEP drawings, providing an overview of the entire project to the stakeholders. These drawings reflect how the components come together and formulate an entire structure.

Compliance and Legal Documentation

These drawings are referred to as legal and regulatory compliance documents, ensuring the project is designed according to the industry codes.

Design Intent

The construction drawings provide an elaborative representation of the architect’s design intent and vision. These drawings act as a blueprint for the construction team to follow.

Advantages of Shop Drawings

Quality Control

These drawings provide rigorous quality control during the manufacturing or construction process. The quality control ensures that the design aligns with the industry standards and norms.

Collaboration

It regulates a streamlined collaboration between various stakeholders, including architects, contractors, engineers, and manufacturers, promoting better teamwork, problem-solving, and communication.

Detailed Design Information

These drawings include detailed information about individual building components, including exact measurements, manufacturing methods, assembly instructions, and material information, and ensure that the final deliverable matches the proposed design.

Clarity

This set of drawings eliminates ambiguity and misunderstandings, reducing the chances of errors, rework, and miscommunication.

Customization

The shop drawings provide the scope of customization to the contractors or manufacturers. They can tailor certain details as per the project requirements or occurring constraints on-site during construction.

What are the Inclusions of These Drawings?

Construction Drawings

- Plans (Framing, roof, electrical, utility, and lighting)

- Elevations (exterior and interior)

- Sections ( building and walls)

- Door and window schedules

- Interior, exterior, and structural details

- Finishes

- MEP data

Shop Drawings

- Interferences and adjacent component details

- Level and material tags

- Location and size of openings

- Component coordinates for site surveying and site location

- Views of the building sections

- Component identification with tags and dimensions

- Clearance needs and assembly details

- Order and sequence of each shop drawing

- Installation and erection data

- Fabrication standards

- Notes including deviations, changes, and dimensions

- Initial submission date of drawings and revision dates with description

- Title block including the project name, number, general notes, abbreviations, subcontractor names, general notes, and legends

Key Differences Between Construction & Shop Drawings

In the architecture, engineering, and construction (AEC) industry, understanding the distinction between construction drawings and shop drawings is essential for smooth project execution. While both are critical components of the documentation process, they serve different purposes and audiences.

Let’s break down the key differences:

| Purpose and Use | |

|---|---|

| Construction Drawings are prepared during the design phase to convey the overall design intent. These include general layouts, dimensions, materials, and compliance details used for permits, bidding, and project coordination. | Shop Drawings, on the other hand, are created after the contract is awarded. They translate the design into precise fabrication and installation instructions. These drawings focus on "how" components will be built and installed on site. |

CAD Drawing Services often produce construction drawings that guide the project vision, while Shop Drawing Services focus on component-level accuracy and constructability.

| Level of Detail | |

|---|---|

| Construction Drawings offer a broader view with typical plans, elevations, sections, and notes necessary for code compliance and coordination. | Shop Drawings zoom into the finer details—showing exact dimensions, assembly instructions, tolerances, and manufacturer specifications. |

When enhanced with 3D BIM Modeling, shop drawings can detect clashes early, ensuring conflict-free installation and reducing costly rework.

Who Prepares Them

- Construction Drawings are developed by architects, structural engineers, and MEP consultants.

- Shop Drawings are created by contractors, subcontractors, fabricators, or specialty vendors, often using inputs from 3D BIM Modeling platforms like Revit or Tekla.

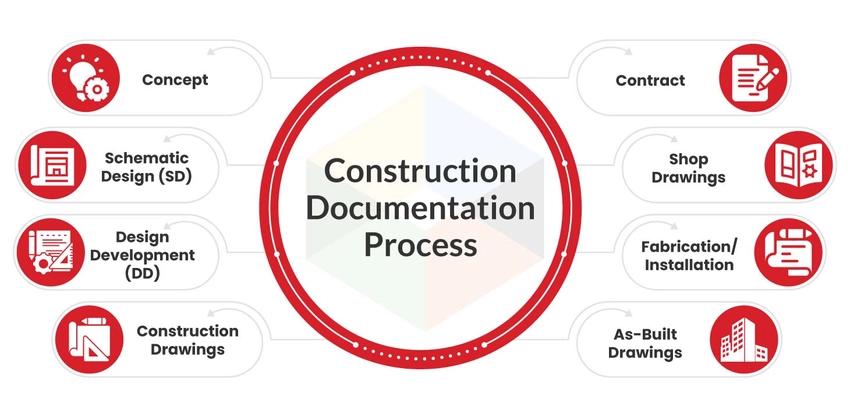

Timeline in the Project Lifecycle

Construction Drawings are generated before construction begins, used for tendering and approvals. Whereas, shop drawings are prepared post-award and prior to fabrication or installation, often requiring approval from design consultants before proceeding.

Approval Process and Liability

Construction drawings are generally marked as “Issued for Construction (IFC)”, but they may include disclaimers like “Not for Construction” when under development.

Shop drawings are submitted for approval and become legally binding documents once stamped, making them crucial to ensure accuracy and accountability during execution.

Both drawing types are indispensable. Construction drawings offer a top-level view, while shop drawings bring precision and buildability to life. Integrating both with CAD Drawing Services, Shop Drawing Services, and advanced 3D BIM Modeling helps streamline communication, minimize errors, and ensure on-time, on-budget delivery.

Construction Drawings vs. Shop Drawings – Quick Comparison

| Feature | Construction Drawings | Shop Drawings |

|---|---|---|

| Prepared by | Architects and Engineers | Contractors, Subcontractors, Fabricators, or Suppliers |

| Detail Level | General layout, design intent, overall coordination | Highly detailed for fabrication, installation, and procurement |

| Purpose | Communicate design for bidding, permitting, and coordination | Guide actual construction, manufacturing, or installation |

| Timeline | Created during the design phase, before construction starts | Developed after contract award, prior to material ordering/fab |

| Content | Floor plans, sections, elevations, schedules | Component dimensions, fabrication specs, installation methods |

| Review/Approval | Reviewed by permitting authorities and general contractors | Reviewed/approved by an architect or engineer before use |

| Liability Note | Often marked “Not for Construction” or “Issued for Coordination” | Considered binding for execution once approved |

| Software Used | AutoCAD, Revit, ArchiCAD | Revit (for BIM), Tekla, SolidWorks, AutoCAD, Inventor |

| Dependency | Based on design standards and codes | Based on construction drawings, RFIs, site conditions |

Liabilities and Disadvantages Associated with These CAD Drawing Services

Construction Drawings

- These drawings are labeled as ‘not for construction’ to eliminate the risks for owners during the construction process on-site.

- Contractors refer to these drawings to align the work with the budget and produce change orders if any detail is left out.

- The drawings represent the actual and complete scope of work for the project.

- These drawings lack the level of detail required for project execution, making it necessary to generate shop drawings for on-site construction.

- The lack of details with these drawings and the absence of shop drawings might cause potential misinterpretation regarding how certain components will be manufactured or installed on-site.

Shop Drawings

- These drawings are approved or require the consent of the construction team to be processed further on-site for construction work.

- Shop drawings reflect the entire scope of work of the contractor with in-field conditions.

- After the project commencement, these drawings are regularly referred to and cross-examined with the site work to achieve accuracy and quality-oriented construction.

- The drawings are manually assembled, step-by-step, during the build process after drafting as per the approved standards.

- The preparation of shop drawings is time-consuming due to the required detailed information, impacting the project timelines and causing delays.

- Producing comprehensive shop drawings is costly and can be a drawback in the case of tight project budgets.

Conclusion

Construction drawings and shop drawings play a comprehensive role in the construction, maintenance, and renovation process of a structure. Construction drawings offer a broader project overview, while shop drawings provide precision and customization.

A combination of both sets of drawings is employed to strike a balance between efficiency and detail. Mindful investment of time and money into these CAD drawing services fuels the completion of a construction project with the desired quality and precision.