The Hidden Cost of Poor Trade Sequencing

You’re halfway through the project, and suddenly, ductwork clashes with structural steel. The plumber’s already installed the pipes. The GC is furious. Sound familiar?

This scenario plays out far too often in small to mid-sized MEP firms, where poor trade sequencing during coordination leads to last-minute changes, field rework, and costly delays. These aren’t just minor hiccups; for every project where sequencing is ignored or mismanaged, MEP contractors can lose up to $50,000 per project due to:

- Labor hours spent on rework

- Material waste from misfabrication

- Crew downtime waiting for resolution

- Penalties from missed deadlines

The frustrating part? These losses are preventable.

In this article, we’ll break down what trade sequencing really means in the context of MEP coordination, the key missteps that lead to coordination breakdowns, and how leading MEP teams are resolving it with smarter workflows, not bigger teams.

Let’s dissect the mistake that’s quietly draining your margins—and how to stop it.

Let's Define – What is Trade Sequencing?

Trade sequencing in MEP coordination refers to the planned order in which various mechanical, electrical, plumbing, and fire protection systems are designed, modeled, and installed, both virtually and on-site. It’s not just about who goes first; it’s about how each trade aligns with structural, architectural, and other systems to minimize clashes and rework.

Without proper sequencing:

- Coordination becomes reactive instead of proactive

- Fabrication is based on outdated or conflicting layouts

- On-site crews face delays due to unresolved overlaps

Effective trade sequencing ensures smooth handoffs, accurate prefabrication, and fewer costly surprises in the field.

The Costly Mistakes of Poor Trade Sequencing in MEP Projects

Trade sequencing refers to the planned order in which MEP subcontractors execute their scope of work during construction. It plays a critical role in ensuring that each system is installed efficiently, without conflicts or costly rework. Yet, this is where many MEP firms lose control.

The Problem:

Improper sequencing can derail a project. Take this common example: electrical rough-ins are completed before HVAC ductwork is installed. When duct routes are later finalized, they clash with conduit paths, forcing the electrical team to reroute systems at their own cost, burning time, labor, and materials. Multiply this across multiple trades, and the budget spirals quickly.

Why It Happens?

- Lack of pre-construction BIM coordination: Without early alignment through BIM or design meetings, trades work in isolation, unaware of spatial conflicts.

- Assumptions about “standard” sequencing: Teams follow outdated rules of thumb without validating them against the actual building design.

- Design conflicts or last-minute changes: Incomplete or late design updates can disrupt even a well-planned sequence, leading to reactive decisions in the field.

For MEP firms, these issues are not just frustrating; they're expensive. Addressing them requires proactive MEP BIM coordination and trade-specific 3D modeling strategies that prevent missteps long before boots hit the jobsite.

The Cost of Wrong Trade Sequencing in MEP Coordination

When trade sequencing goes wrong, the financial impact is anything but minor. For small and mid-sized MEP firms, the cost of a single poorly coordinated project can exceed $50,000, not from one big mistake, but from a series of compounding issues that snowball as the job progresses.

Let’s break down where that $50K loss often comes from:

| Cost Factor | Estimated Loss (USD) | Description |

|---|---|---|

| Labor Wasted on Rework | $15,000 – $18,000 | Rework can cost up to 5% of the total project cost and 7.1% of work hours. Reinstalling systems due to layout errors is a major contributor. |

| Idle Crew Time | $8,000 – $10,000 | Idle time is a known profitability killer. A Harvard study estimated over $100B lost annually in the U.S. due to idle labor. Even a few days of downtime for a small crew can easily hit this range. |

| Material Waste and Reordering | $5,000 – $7,000 | Poor planning leads to waste and reordering. Costs include disposal, storage, and repurchase of specialty items. |

| Rescheduling Inspections, Deliveries & Subcontractors | $4,000 – $6,000 | Delays ripple through crane rentals, inspections, and subcontractor schedules. Rework alone can inflate costs by 5% of project value. |

| Damaged GC Relationships (Opportunity Cost) | $10,000+ (Opportunity Cost) | While intangible, losing future bids due to poor coordination can cost tens of thousands. Opportunity cost theory supports this as the foregone value from next-best contracts. |

| Total Estimated Loss per Project | $50,000+ | A combination of hard costs and long-term business impact. |

Beyond these direct losses are hidden costs that are harder to measure but just as damaging:

- Team burnout: Constant rework and chaos in the field demoralize your crew and increase turnover.

- Legal exposure: Extended delays and scope changes can escalate into disputes or even lawsuits.

- Damaged reputation: GCs and clients talk. One poorly executed project can hurt your firm’s standing across the entire region.

For trade contractors operating on tight margins, even one misstep in trade sequencing can turn a profitable job into a loss. Preventing this requires not more manpower, but smarter planning and coordination.

Why Small MEP Firms Suffer Most from Trade Sequencing Mistakes

Small and mid-sized MEP firms are especially vulnerable to trade sequencing errors, not because of a lack of skill, but due to resource constraints and workflow gaps.

Here’s why the impact hits harder for Small and mid-sized MEP firms :

- Limited BIM expertise or in-house coordination teams means clashes are often detected too late, if at all.

- Coordination tends to be reactive, handled only when issues arise on-site rather than during design.

- General contractors push for speed, pressuring teams to proceed without proper sequencing or approvals.

- No standardized QA/QC process makes it harder to flag coordination errors before fabrication or installation.

The result? Cost overruns, project delays, and frustrated clients.

Fixing the Problem: Strategies to Optimize Trade Sequencing

The most effective way to prevent costly trade sequencing errors is to shift from reactive coordination to proactive planning, starting early with a well-defined BIM Execution Plan (BEP). This foundational document sets the tone for how trades will collaborate, coordinate, and sequence their work throughout the project lifecycle.

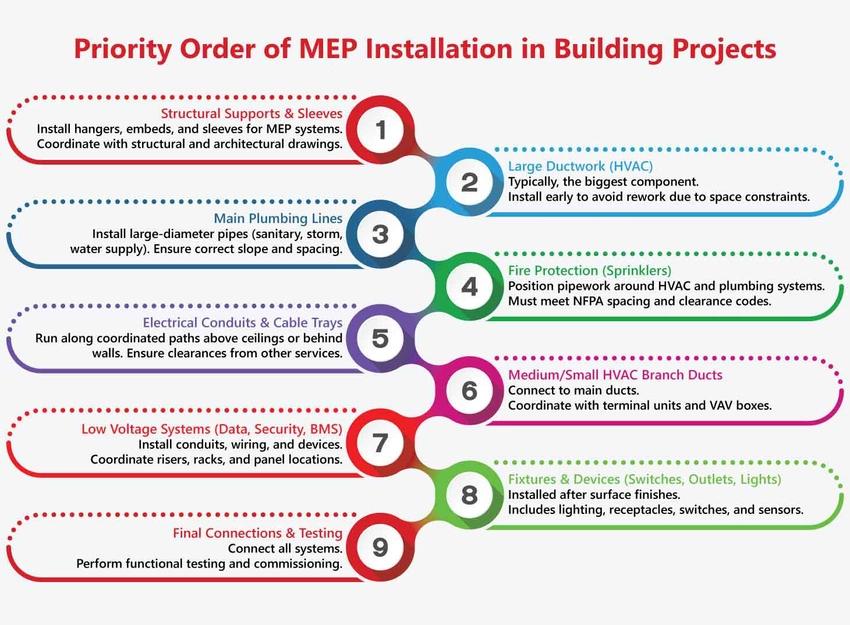

Here’s how MEP firms can implement smarter sequencing strategies:

- Establish a BIM Execution Plan (BEP): Clearly define coordination protocols, model responsibilities, and deliverables before modeling begins.

- Define Sequencing Rules and Lead Trades: Assign primary trade responsibility, like HVAC leads vertical shafts, and so on, to avoid clashes in constrained spaces.

- Use Phased or Zone-Based Modeling: Break the project into manageable areas to streamline coordination and isolate issues before they escalate.

- Adopt a Lead Trade Strategy: Prioritize routing of the dominant trade, typically HVAC, so others can route around it efficiently.

- Assign Coordination Responsibility: Don’t assume someone else will handle it. Designate a BIM coordinator or bring in external experts.

- Run Clash Detection Early and Often: Don’t wait for preconstruction reviews. Catch and resolve conflicts in the design phase using tools like Navisworks or Revit.

Early, structured coordination helps MEP teams stay on schedule, reduce rework, and keep profit margins intact, without expanding headcount.

How Small MEP Teams Solve Trade Sequencing Challenges—Without Building a BIM Department

Small MEP firms often lack the bandwidth to build a full-scale in-house BIM team, but that doesn’t mean they can’t coordinate effectively. Many are turning to scalable, expert-driven solutions to eliminate trade sequencing issues without the overhead.

Here’s how agile MEP teams are tackling the challenge:

- Outsourcing MEP Coordination to BIM Specialists: External BIM experts handle clash detection, model integration, and sequencing logic, freeing your team to focus on field execution.

- Using Dedicated Resource Models (DRM): Instead of hiring full-time, firms tap into on-demand BIM talent who work as an extension of their internal team, ensuring consistent support without long-term commitments.

- Leveraging Navisworks or Revit with External Coordination Help: Internal teams use familiar modeling platforms, while outsourced coordinators handle clash detection and BIM 3D model audits using advanced workflows.

- Implementing Standardized QA/QC Templates: Repeatable checklists and review protocols help catch sequencing issues early, before they turn into change orders.

These approaches enable small MEP contractors to achieve the same level of coordination as larger competitors, without the cost or complexity of a full BIM department. It’s a lean, efficient way to stay competitive in fast-paced projects.

Conclusion:

Trade sequencing mistakes can quietly drain over $50,000 per project through rework, delays, and lost opportunities. But the solution doesn’t require a massive team or high overhead; it requires proactive coordination and process-driven planning.

You don’t need a 10-person VDC team to avoid $50K mistakes. You just need the right process and the right support.

Looking to streamline your MEP coordination without hiring in-house?