Why Your QC Team Is Losing Time on Field Validation

In the fast-paced AEC industry, time is a critical asset, especially for Quality Control teams juggling tight schedules, multiple trades, and compliance requirements. Yet, many teams still struggle with:

- Scattered site data and handwritten inspection notes

- Delays due to unclear documentation and approval loops

- Frequent rework from unverified installations

- Misalignment between on-site conditions and coordinated drawings

At the heart of these challenges is one root cause: inconsistent or manual field validation. Without a standardized, checklist-driven process, inspections become reactive, fragmented, and error-prone.

That’s not just saved hours; it’s faster approvals, fewer disputes, and less rework.

In this blog, we’ll show you exactly how to build a smart field validation checklist tailored for MEP systems that accelerates your QC process without compromising accuracy.

Why QC Teams Waste Time on Field Validation

For MEP contractors and engineers, the field validation process is crucial, but it’s also where time and resources are most often lost. Despite advancements in digital construction, many QC teams continue to operate with outdated or inefficient methods that slow them down and increase the risk of costly rework.

Here’s where the time drain typically happens:

No Standardized Validation Framework

Without a consistent checklist or validation protocol, field teams often verify items based on personal judgment or fragmented instructions. This leads to inconsistent inspections and missed critical elements.

Redundant Inspections & Ambiguous Documentation

When validation data is vague or incomplete, multiple rounds of site visits become necessary. QC engineers may have to reconfirm dimensions, materials, or installations that were already checked, wasting both time and manpower.

Manual Data Collection Still Prevails

Many teams still rely on paper-based checklists, handwritten notes, or unstructured digital formats like WhatsApp images or scattered PDFs. This makes it difficult to track validation status, maintain traceability, or ensure version control.

Disconnection from Design and BIM Models

Without proper integration between field activities and design documentation, teams often validate installations without real-time reference to coordinated models, increasing the risk of non-conformance.

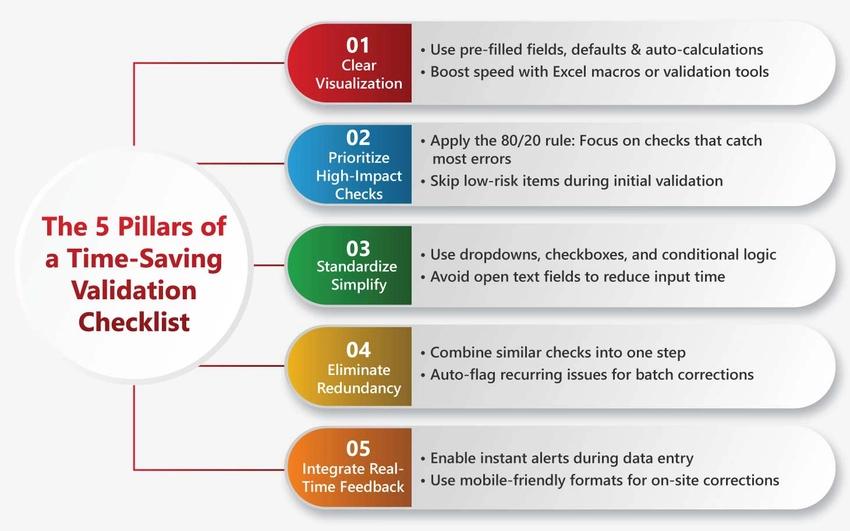

Solving these challenges starts with creating a structured, model-aligned checklist that acts as a single source of truth, one that not only reduces validation time but also improves field accuracy and accountability.

Key Components of an Effective Field Validation Checklist for MEP Projects

A well-structured field validation checklist isn't just a document; it’s a critical quality control tool that drives efficiency, accuracy, and accountability across MEP inspections. For contractors and engineers, the right checklist streamlines the verification process, prevents costly rework, and ensures every system is installed and documented correctly the first time.

Here’s what a robust, time-saving field validation checklist should include:

Categorized by Discipline

Organize checklist items by trade, like Architecture, MEP, Structural, Fire Protection, so field teams can quickly focus on their scope of work. This also helps prevent cross-disciplinary oversight and ensures accountability.

Clear Validation Items with Success Criteria

Each checklist entry should define:

- What needs to be verified, such as pipe diameter, duct routing, equipment clearance, etc.

- How success is measured, for example, within ±10mm tolerance, matches the shop drawing, complies with code, etc.

This eliminates ambiguity and reduces the need for repeat inspections.

Required Field Evidence

For every validation item, define the documentation required:

- Photos from specific angles

- Measurements using calibrated tools

- Marked-up drawings or sketches for deviations

Including this upfront ensures uniform reporting and smooth approvals.

Status Tracking (Complete/Incomplete/Pending Review)

Incorporate a status column that enables teams to mark items as:

- Complete

- In Progress

- Rejected / Needs Rework

This provides real-time visibility into progress and bottlenecks.

Assigned Personnel & Deadlines

To avoid confusion, assign:

- Responsible person for validation

- Due dates for meeting inspection milestones

This ensures that accountability is built into the process, improving coordination across teams.

Digital-Friendly Format

Paper checklists are slow, error-prone, and hard to track. Instead, opt for:

- Mobile forms or apps, like BIM 360 Field, PlanGrid, Procore, etc.

- BIM-integrated checklists that pull directly from the model

- Cloud-based storage for easy sharing and review

Digital tools allow inspectors to upload photos, mark deviations on the spot, and sync data with the project team instantly.

Pro Tip: Use templates aligned with your BIM model sheets or coordination drawings. This minimizes redundant field checks and ensures validation happens against the latest design data.

A checklist built with these components does more than just guide inspections; it becomes a live tool for real-time QC tracking, documentation, and cross-team collaboration. For MEP contractors, this structure is key to cutting wasted effort and completing validations on time and with confidence.

Tools That Can Help Speed Up Field Validation for MEP Teams

For MEP contractors and engineers, selecting the right tools can dramatically streamline field validation, reducing inspection time, improving accuracy, and minimizing rework. Here are some proven platforms and technologies that accelerate the process:

- BIM 360 Field or Autodesk Build: These cloud-based platforms allow real-time issue tracking, punch list management, and model-linked inspections. QC teams can validate directly against coordinated BIM data, ensuring field conditions match design intent.

- Bluebeam Revu: Ideal for teams that rely on annotated PDFs. Bluebeam allows field teams to mark up drawings, add photos, and track revisions. Its batch comparison tools speed up the review of as-built vs. design plans.

- PlanGrid: PlanGrid simplifies access to drawings, checklists, and RFIs on mobile devices. Field teams can complete validation checklists, attach photos, and flag issues, all from the jobsite.

- Custom Digital Forms: Platforms like Google Forms or Jotform let you build project-specific checklists with logic, file uploads, and real-time submission tracking. Great for teams seeking lightweight, customizable solutions.

- Laser Scanning + Point Cloud Overlays: Use 3D scans or point clouds to compare existing conditions with the BIM model in tools like Navisworks or Revit. This helps QC teams validate element locations, dimensions, and clearances with unmatched precision.

Using the right combination of these tools can drastically cut down manual effort, improve coordination, and deliver validation reports that are both fast and reliable.

Real Benefits of a Checklist-Driven Approach in MEP Field Validation

For MEP contractors and engineers managing complex installations under tight timelines, a checklist-driven validation process offers far more than organization; it delivers measurable project benefits.

Here’s how:

- Cuts Down Repetitive Inspections: Well-defined validation checklists reduce ambiguity and ensure inspectors don’t miss critical checks, eliminating the need for multiple rounds of verification.

- Improves Documentation for Audits and Handover: Each checklist item includes evidence like photos, measurements, markups, etc., creating a structured digital trail that’s ready for compliance reviews, certifications, or owner handoffs.

- Reduces Miscommunication with Field Teams: With clear pass/fail criteria, assigned responsibilities, and status tracking, teams spend less time clarifying tasks and more time executing them correctly.

- Speeds Up Approvals and Sign-Offs: Digitized checklists can be shared in real time, enabling faster responses from supervisors, consultants, or project managers, reducing bottlenecks.

- Enhances Accuracy of As-Built Conditions: Integrated validation ensures verified field conditions are accurately reflected in the final as-built model or documentation, improving long-term asset reliability.

- Boosts Team Efficiency and Professionalism: A checklist-driven approach positions your QC team as precise, proactive, and audit-ready, building client trust and internal accountability.

For MEP projects where every minute counts, this structured approach is a clear step toward faster, smarter, and more reliable execution.

Conclusion

A well-structured field validation checklist isn’t just a tool; it’s a system upgrade for your entire QC process. By standardizing inspections, integrating real-time documentation, and eliminating manual inefficiencies, you transform a traditionally slow and error-prone task into a streamlined, repeatable workflow. For MEP contractors and engineers, the result is fewer delays, improved accuracy, and smoother coordination between design and field execution.

Backed by research and proven in practice, a checklist-driven approach can cut field validation time by up to 30%, a strategic gain in today’s competitive AEC industry.

Ready to speed up your field validation?

Start by building a checklist aligned with your BIM models and field team workflows. Accelerate your MEP BIM projects with precision, flexibility, and accountability, every step of the way.